IDEAL FOR INDUSTRIAL WET MILLING AND WET GRINDING

IDEAL FOR INDUSTRIAL WET MILLING AND WET GRINDING

Excellent Stability - Reliable Performance - High Efficiency:

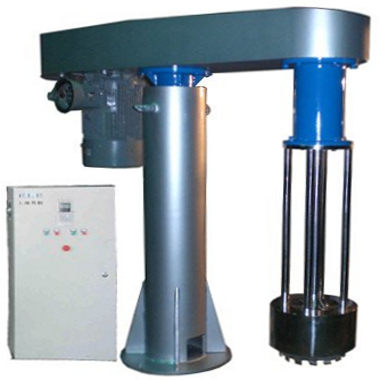

Product Information - Industrial Basket Pearl Mills:

Qualtech Products Industry Wet Grinding Basket Pearl Mills combine professional dispersing with efficient milling in a single procedure. This model of Wet Grinding Basket Mills integrates the functions of pre-dispersing, fine grinding and eventually spread into one production machine. This Wet Grinding Basket Pearl Mill is designed to realise high milling efficiency and fine milling effects. This Wet Grinding Basket Pearl Mill is easy to clean and build to operate highly efficient for less residual arrears. This Wet Grinding Basket Mill realizes high milling efficiency and achieves a fine milling effect for a successful applications in your production lines. Industrial Wet Grinding Basket Pearl Mills are usually applied in pigment, dyestuff, oil paint, ink, color paste, paint, pharmaceutic and cosmetic industries and many more.

Details - Industrial Basket Pearl Mills:

This Wet Grinding Basket Mill operates with a liquid circulation system which is generated between the material feeding rotor and toothed dispersing disc and grinding beads with high hardness driven by the high-speed rotating pole in the basket to achieve an outstanding milling effect. Good milling fineness, high grinding efficiency, even particle distribution are some of the advantages of this Wet Grinding Basket Mill designed to complete the whole milling process under closed conditions. Without dead corners, little residue and easy to clean this type of Wet Grinding Basket Mill is one of the best suitable production machines for industrial production environments. This Wet Grinding Basket Mill can be ordered with an optional clamp to fix stainless steel containers during operation. This Wet Grinding Basket Mill is easy and safe to operation and fits well and conveniently into your production lines. The cover is mirror polished, easy to clean offering a nice appearance.

Features - Industrial Basket Pearl Mills:

- Integrates the dispersing and grinding process into one machine

- Convenient to change the grinding material

- Less residual to save production costs

- High grinding efficiency with even particle distribution

- Convenient hydraulic lifting system is easy to maintain

- Advanced efficiency even for high viscosity material

- High speed rotating disc for fast production results

- Easy to change the color or product, one machine can be used to produce many kind of different products due to easy cleaning system

- Can be well combined with a portable stainless steel tank (optional)

- Clamps available to fix containers (optional)

- Variable speed control to adjust operation speed to your production requirements

- Easy to use, designed for one person operation, several equipments can be operated by one person

- Explosion proof models available

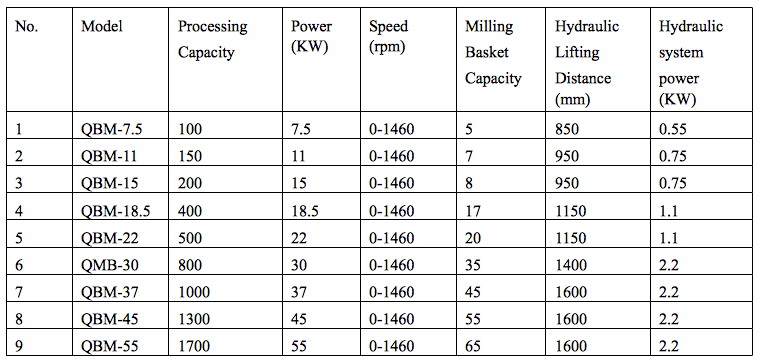

Specifications - Industrial Basket Pearl Mills:

- Power: 7.5KW-55KW

- Voltage: 380V/50Hz or 460V/60Hz (please specify when ordering)

- Type of motor: Frequency and Explosion-Proof (please specify when ordering)

- Range of speed: 0-1460RPM

- Handling capacity: 10-2000L

- Contact material: SUS304 (stainless steel 304)

- Material of grinding plate: Hard ceramics zirconia (outside) and stainless steel (inside)

- Grinding media: Zirconia balls(2-2.4mm)

- Lifting Type: Hydraulic

Available Models - Industrial Basket Pearl Mills:

Description Design and Details of this Wet Grinding Basket Mill:

| SUCTION | GRINDING | CIRCULATION | SEPARATION |

The performance of the Wet Grinding Basket Mill can be described with four stages:

- Suction

- Grinding

- Circulation

- Separation

During the initial stage of material feeding of the Wet Grinding Basket Mill material is drawn into the basket created by the strong suction of the impeller in the basket. The Beads in the Basket of the Wet Grinding Basket Mill are driven by the Deflector Rod which rotates at a very high speed. In the further run the Beads in the basket of the Wet Grinding Basket Mill grind the material to almost instantly achieve super fineness. A high speed dispersing disk rotates at a very high speed to generate a strong centrifugal force at the bottom of the basket. In addition the Self-Suction Impeller draws the material after superfine grinding for dispersion and ejection based on a highly efficient circulation.

Wet Grinding Beads used in the Basket of the Wet Grinding Basket Mill:

The Wet Grinding Beads used in the Industrial Basket Pearl Mills are of excellent quality with an outstanding grinding effect to offer high efficiency, little abrasion and our Grinding Beads do not polute the material.

View Similar Products

PROFESSIONAL EQUIPMENTS FOR YOUR PRODUCTION LINES - REAL VALUES FOR OUR CLIENTS

Production Dispersers

IDEAL FOR INDUSTRIAL DISPERSION

Basket Pearl Mills

IDEAL FOR INDUSTRIAL WET MILLING AND WET GRINDING

Production Mixers

IDEAL FOR INDUSTRIAL MIXING

Horizontal Sand Mills

IDEAL FOR INDUSTRIAL MILLING AND GRINDING

Vertical Sand Mills

IDEAL FOR INDUSTRIAL MILLING AND GRINDING

Three Roll Mills

IDEAL FOR INDUSTRIAL MILLING

Mixing Reactors and Tanks

Professional Mixing Tanks with Mixer Built In

Stainless Steel Mixing Containers

Ideal Mixing Vessels For Your Production Lines

Accessories

Premium Dispersion Blades and Premium Pearl Baskets